Bits Behind Atoms: Using AI to Design Building Systems

Note: This is a cross-post between this site and Eclipse’s blog.

The construction industry represents 14% of the U.S. GDP, or $2.1 trillion annually. At such a scale, improvements to standard workflows yield a significant impact on productivity and sustainability. Yet, the industry suffers from chronic inefficiencies, lagging far behind in automation compared to other sectors. It’s plagued with legacy tools and manual processes, leading to errors, excessive material waste, and carbon emissions.

Construction Engineering is a labor intensive, iterative, and error-prone process. Outdated modeling tools, often decades old, are still in use. Among the most demanding and challenging parts of this process is designing the mechanical, electrical, plumbing, and structural systems (MEP+S) that comprise the internal “guts” of a building.

Given the size of the market opportunity and deficiencies of existing manual processes, it’s natural to ask: why hasn’t there been more technological progress in construction?

Imagine a world where construction projects leverage AI at-scale to generate all conceivable building designs in seconds. Until now, many of the technical hurdles in building such a tool have been insurmountable. However, this is just one of the many challenges Eclipse portfolio company Augmenta set out to solve.

Today, we’re sharing some of the most interesting technical challenges Augmenta is tackling to bring this vision to life.

Tackling hard-to-scale combinatorial problems

Let’s start with Augmenta’s approach to automating the design for electrical systems. Given known electrical sources and destinations inside a building, Augmenta’s software automatically generates routes for wires, raceways, and supports inside a structural “shell” provided as a 3D model.

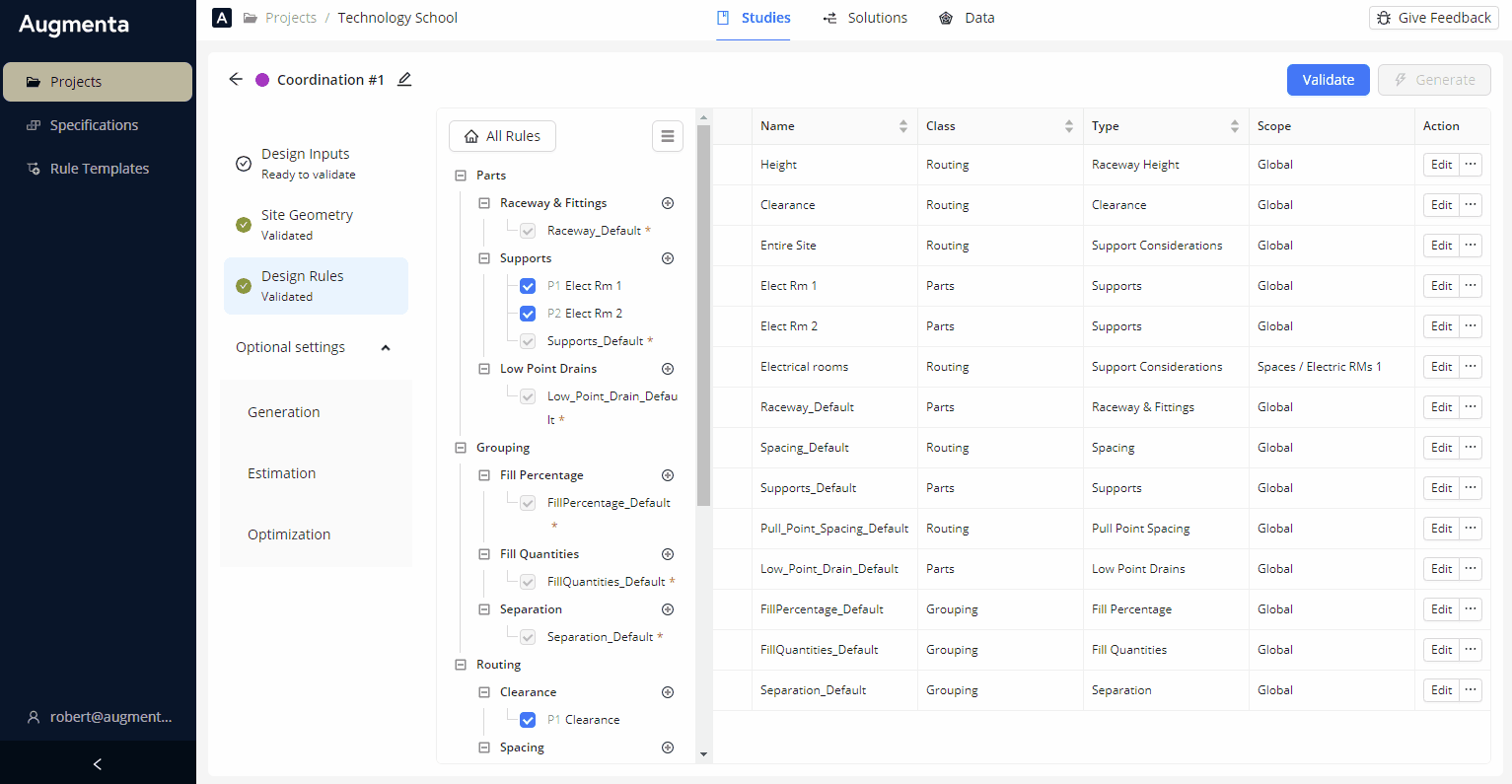

The system analyzes the spatial and structural aspects of a building model, understanding and cataloging key characteristics, such as the usage and distribution of materials across supporting structures like walls, beams, columns, etc. It then uses all the collected site information and building code knowledge to make informed design decisions about optimal wire sizing, grouping, routing, and detailing of exact parts that comprise the system.

Taken together, this generates code-compliant, cost-effective designs.

Augmenta Construction Platform (ACP) combines complex 3D site data, multi-modal user input, and extensive building code-driven rules to generate a range of highly optimized designs.

Generating these designs involves placing and routing parts inside a CAD model in a 3D design environment, adhering to rules and regulations, part constraints, constructibility requirements and tribal knowledge. Put another way: it’s like hand-painting a travel route in Google Maps, except it’s now in an 8-dimensional space with rigid, restrictive traffic rules to follow, like “only red trucks can turn left at intersections where there are 3 lanes.”

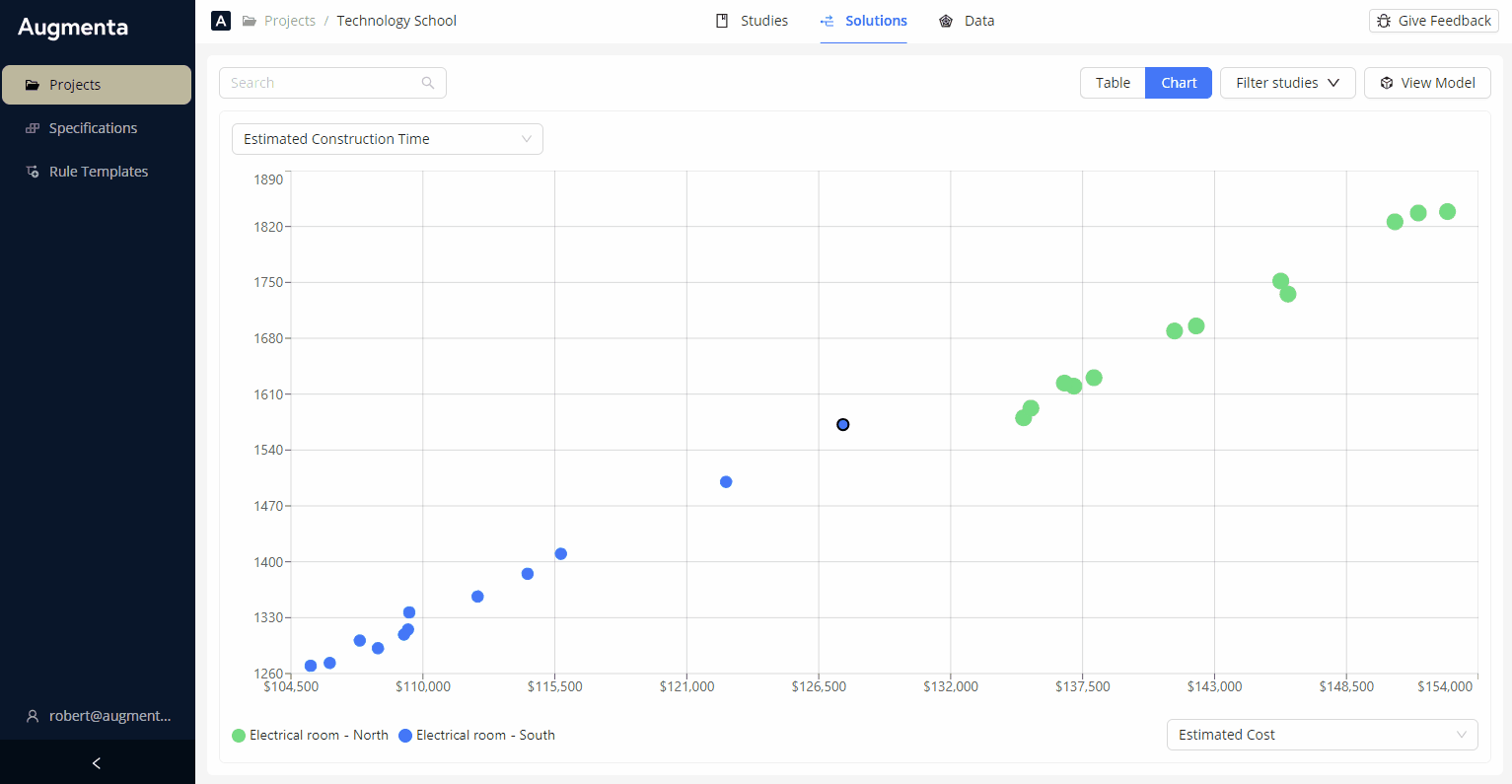

Traditionally, Building Information Modeling designers spend weeks, or months, on a single design. Augmenta Construction Platform (ACP) automatically generates multiple designs, modeling multiple electrical routing options, in just hours or even minutes.”

A vast space of infinite possible solutions

Generating solutions to this problem is known as an “NP-hard” problem in computer science, in which there are too many possible solutions for a computer to churn out in a reasonable time period. The challenge for Augmenta is to constrain the backend to produce a select number of relevant designs.

Among the major hurdles in generating solutions are strict and complex circular dependencies. Consider the task of automatically selecting a wire gauge. The gauge of the wire depends on various factors, such as length. The length, in turn, is determined by where the wire starts and ends, and the path it takes in between. The chosen path is influenced by the space available for the raceway, which is where the wire and its supporting hardware fit. In building design, there are many code compliance rules that determine where electrical raceways can be placed. These rules create numerous possible paths for the wire to follow, each resulting in a different wire length. The length of the wire affects its thickness and, consequently, the size of the raceway needed to accommodate it. If the chosen raceway no longer fits the originally-planned path, a new plan needs to be selected. This restarts the cycle, as the new path will have different lengths, impacting both the wire gauge and the required raceway size.

Augmenta’s approach to solve these combinatorial optimization challenges is a mix of classical AI and generative Machine Learning (ML) techniques. The classical AI part of the system uses advancements in fundamental algorithms and data structures, ensuring designs are not only feasible, generated efficiently, but also economical and code-compliant.

In this journey, there are numerous open challenges that require advancing the state of the art to tackle the longtail of all conceivable designs in seconds. For example, Augmenta’s software, called ACP, needs to be able to find sensible aggregated routes in high-density scenarios, such as large electrical rooms of big data centers. This requires a dedicated approach to route selection to ensure constructibility. To do so, ACP must use ML to pre-process and reduce the design space, splitting the problem into portions that can be computed in parallel on multiple machines.

Building actionable AI, not assistive AI

Generative design systems traditionally rely on mathematical optimization, conventional ML, or advanced techniques like Deep Learning (DL) with Generative Adversarial Networks, Diffusion Models, or Large Language Models (LLMs). But posing the building engineering design problem as a pure mathematical problem makes it hard to scale given the sheer size of the design space.

DL-based solutions operate on the concept of features and the statistical probabilities of the presence of those features within a design — either as a whole or as represented by a sequence of operations. Very seldom do they have hard constraints to satisfy. Solely relying on pure generative models based on LLMs and Reinforcement Learning makes these approaches intractable, even with support from advanced mathematical toolkits. While standalone generative AI models are useful for unconstrained creative applications, physical-world problems have strict constraints, making probabilistic approaches generally unsuitable.

Modern generative systems that create images or videos produce designs deemed “valid” only to the extent that they incorporate the semantic features requested by the user. The degree of certainty in which these features are used or mixed correctly is effectively unknown in advance, making them unsuitable to engineering work. While even the most advanced generative systems, which possess vast amounts of semantic knowledge captured from enormous amounts of documentation, can express and explain specific concepts in great amounts of detail, they fail to produce directly actionable designs.

Actionable AI requires a blend of two computational methodologies: leveraging the creativity of generative ML models alongside the mathematical rigor of classical AI. There needs to be a way for generative ML models to get the necessary data and ability to reason more deeply about the essential traits of the built environment. Actionable AI also requires creative solutions to address the geometric computational complexities that permeate this design process.

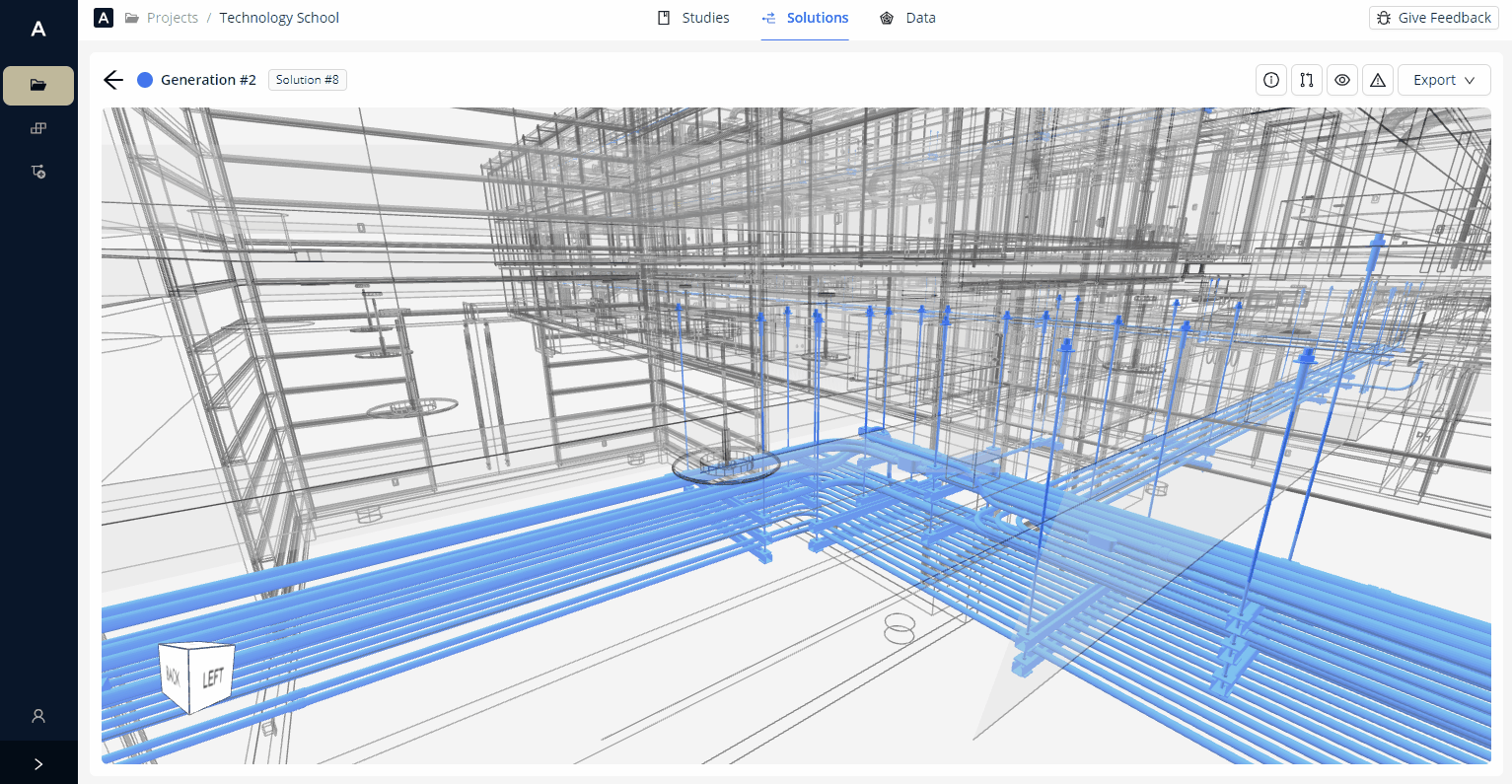

ACP produces actionable, detailed designs that are code-compliant and ready to fabricate, procure and install.

Developing a new architecture for 3D geometry

Effectively encoding 3D geometry features at a large scale is still an unsolved problem in ML, as 3D(4D) space is extremely feature rich and difficult to compress. We’ve seen specialized model architectures emerge in tasks like natural language processing (e.g. Transformers) and image/video generation (e.g. Diffusion). But, despite notable progress, the AI community lacks consensus on the optimal architecture for semantic manipulation of 3D geometry.

ACP works at scale, from the smallest electrical room to highly complex site-wide distribution systems.

Addressing ACP’s multimodal challenges — which integrate semantic and spatial features with correctness constraints — requires adjusting the representation of spatial features and the model architecture itself. ACP has a range of parameters and options to balance system scalability, performance, design optimality, and uncertainty. Leveraging ML, we can search for optimal architectures and parameters using data generated as the system gets more use.

Additionally, since there are very few scalable techniques to semantically represent constrained assemblies of tens of thousands of mechanical parts, we adapted and refined techniques from modern video game engines to tackle specific portions of the design generation and refinement process, such as fine-grained part selection and placement.

The future

Looking towards Augmenta’s future, we see promising advancements in combining ML and numerical analysis. For instance, Physics-Informed Neural Networks play a crucial role in achieving the level of interactivity, precision, accuracy, and scalability that’s needed for generative systems to solve complex, physical problems. It’s improbable that individual ML models alone will suffice in solving large, complex physical problems unless applied to narrow domains. Finding the right combination of mathematical models, computational geometry techniques, and numerical methods will require a concerted effort. Achieving a truly goal-oriented AI requires ongoing innovation and collaboration across several fields of computer science and engineering to solve the challenges presented in this article.

Much like organizations such as DeepMind, known for its groundbreaking advancements in material and drug discovery, and GE, which has made notable progress in the transportation industry leveraging recent ML methods, Augmenta’s pioneering technology is poised to push the field of construction forward. Moreover, Augmenta’s technology paradigm has the potential to revolutionize design across physical industries beyond construction.